- TOP

- Sustainability

- Social

- Quality Management

Quality Management

In April 2022, along with a revision of our Quality Policy, the Nissha Group established the Nissha Quality Way as a code and standard of conduct necessary to actualize the Quality Policy. These are our fundamental philosophies for quality in the Nissha Group and upper level policies for all quality policies currently implemented in the Quality Management System (QMS).

The Chief Quality and Production Officer (CQPO) carries out plant assessments for all our production bases in Japan and major overseas production bases. Additionally, he uses an array of opportunities to spread and percolate our Quality Policy and the Nissha Quality Way, including training at foreign bases, training targeting new employees and promoted employees, and inclusion in internal company publications (published in Japanese, English, and Chinese).

The Chief Quality and Production Officer (CQPO) carries out plant assessments for all our production bases in Japan and major overseas production bases. Additionally, he uses an array of opportunities to spread and percolate our Quality Policy and the Nissha Quality Way, including training at foreign bases, training targeting new employees and promoted employees, and inclusion in internal company publications (published in Japanese, English, and Chinese).

Quality Policy

Nissha Group’s products and services enhance value for customers and society through the establishment and operation of quality management system that is designed to ensure quality, cost, robust supply chains, and compliance with relevant laws and regulations.

Junya Suzuki

Chairman of the Board and Group CEO

Nissha Co., Ltd.

Chairman of the Board and Group CEO

Nissha Co., Ltd.

Nissha Quality Way

- CUSTOMER FOCUS

We continuously achieve customer-defined quality. - LEADERSHIP

We are all committed to upholding and executing our Quality Policy – each and every one of us is a leader. - PROCESS APPROACH

We work based on systematic approach and continue to improve. - QUALITY BY DESIGN

We build quality into design, focusing on product safety and feasibility. - VALIDATED DECISION MAKING

We are established in evidence-based and scientific approach. - QUALITY BY CONNECTED SUPPLY CHAIN

Quality is at the core of our trusting relationship within our supply chain. - BAD NEWS FIRST

We quickly address challenges through rapid response and escalation process.

Yutaka Nishimoto

Director of the Board, Senior Executive Vice President, Chief Quality and Production Officer

Nissha Co., Ltd.

Established on April 1, 2011

Revised on April 1, 2022

Director of the Board, Senior Executive Vice President, Chief Quality and Production Officer

Nissha Co., Ltd.

Established on April 1, 2011

Revised on April 1, 2022

Quality Slogan

For the quality improvement, it is essential to take actions with a strong awareness of customers. Following our Quality Policy revision and the establishment of the Nissha Quality Way, we revised our quality slogan in April 2022. The slogan shows that the protagonist who creates quality is “me”, that is, all employees working in our group. Just as in our Quality Policy and the Nissha Quality Way, we are spreading and permeating this slogan throughout all Nissha Group companies both in and outside Japan.

Quality Management System (QMS)

Out of our belief that the systematization of work is important, the Nissha Group constructs our Quality Management Systems to align with their target markets. We also create quality targets that conform with quality policies as well as planning to meet those targets. This is employed in the process of cycling through PDCA and in our quest to actualize target performance.

In addition to creating, implementing, and continually improving quality control systems based in the international ISO9001 (2015 version), we are steadily constructing quality assurance systems individually aligned with Medical, Mobility, and Sustainable Materials designated as the priority markets in our Sustainability Vision (long-term vision) for where we want to be in 2030.

In businesses oriented towards the Medical market, we have acquired a first-class marketing license for medical devices, an operating permit required to manufacture and sell medical devices within Japan. 14 Nissha Group bases have obtained ISO13485, the international standard for quality management systems in the medical devices industry (as of March 2024).

In businesses targeting the Mobility market, eight Nissha Group factories and support sites have obtained IATF16949 certification for quality management systems in the automotive industry (as of March 2024).

In addition to creating, implementing, and continually improving quality control systems based in the international ISO9001 (2015 version), we are steadily constructing quality assurance systems individually aligned with Medical, Mobility, and Sustainable Materials designated as the priority markets in our Sustainability Vision (long-term vision) for where we want to be in 2030.

In businesses oriented towards the Medical market, we have acquired a first-class marketing license for medical devices, an operating permit required to manufacture and sell medical devices within Japan. 14 Nissha Group bases have obtained ISO13485, the international standard for quality management systems in the medical devices industry (as of March 2024).

In businesses targeting the Mobility market, eight Nissha Group factories and support sites have obtained IATF16949 certification for quality management systems in the automotive industry (as of March 2024).

Two Strategies in the 8th Medium-term Business Plan

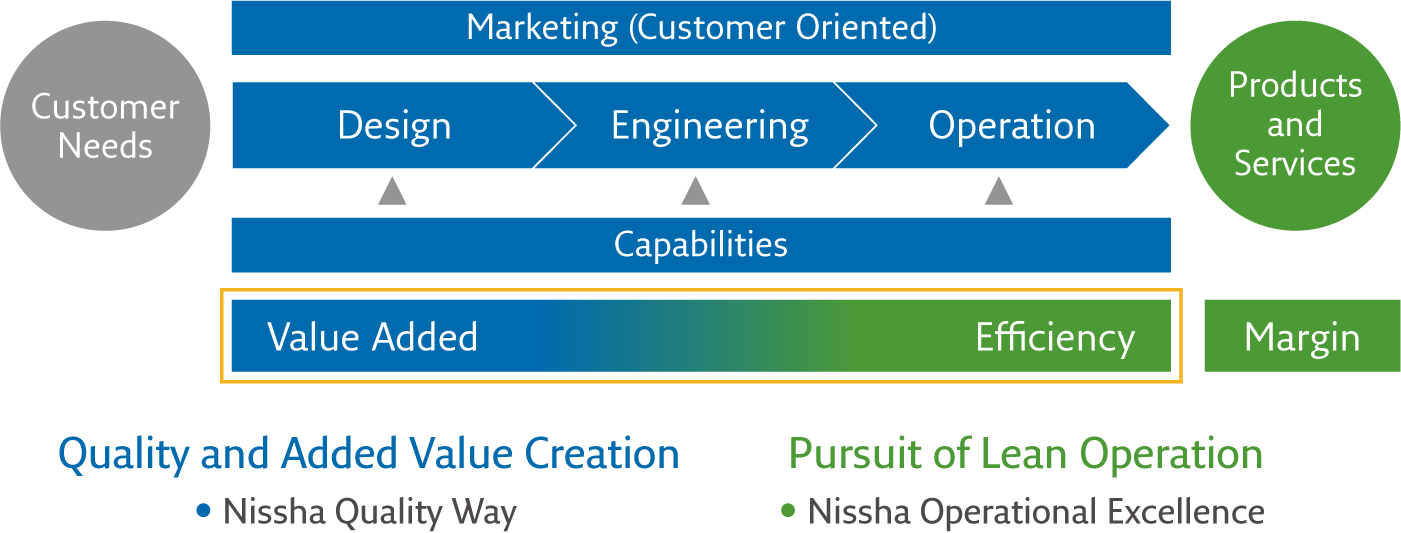

In the quality and production strategy, part of the 8th Medium-term Business Plan (2024-2026), we are working on maximizing profit margins throughout the entire value chain through quality and added value creation at the design and development stages, and the pursuit of lean operation at the mass production stage.

Quality and Safety of Products

Information on product handling and safety is clearly stated in the delivery specifications, etc. to customers. In the unlikely event that an incident involving a defect in our products or services leads to a violation of laws and regulations or a serious accident related to quality assurance, we will respond in accordance with our Regulations for Responding to Serious Quality Incidents and work to resolve the situation as soon as possible. In addition to providing appropriate reports to government agencies in accordance with the law, we have a system in place to inform customers of any necessary information as quickly as possible. Employees are made aware of the importance of ensuring product quality and safety through corporate ethics and compliance training and other programs. As stated in BAD NEWS FIRST in the Nissha Quality Way, we think that when a problem occurs, prompt escalation and early response is an opportunity to strengthen trust from all of our stakeholders, including customers.

The evaluation of our product quality is determined by our customers. The Nissha Group indexes and manages quality performance with factors including quality defects and delivery disappointments communicated by customers as a “customer satisfaction level” index.

In the fiscal year ended December 2023, there were no serious quality incidents or violations (no fines), as defined in the Regulations for Responding to Serious Quality Incidents. We will continue striving to maintain the number of serious quality incidents and violations at zero.

The evaluation of our product quality is determined by our customers. The Nissha Group indexes and manages quality performance with factors including quality defects and delivery disappointments communicated by customers as a “customer satisfaction level” index.

In the fiscal year ended December 2023, there were no serious quality incidents or violations (no fines), as defined in the Regulations for Responding to Serious Quality Incidents. We will continue striving to maintain the number of serious quality incidents and violations at zero.